Paper recycling is the environmentally friendly process of re-using a used paper. Tons of paper are consumed nationwide daily. After being used for documents, writing and printing, they are usually thrown away as scrap.

Unless it is recycled, paper becomes part of garbage dumps and landfills, contributing to problems like greenhouse gas emissions and pollution. Paper recycling can alleviate many of these problems by turning this scrap paper into new paper. It is the need of the hour. According to statistics, about 40% of landfill waste consists of paper. This makes nearly half of the U.S landfills recyclable.

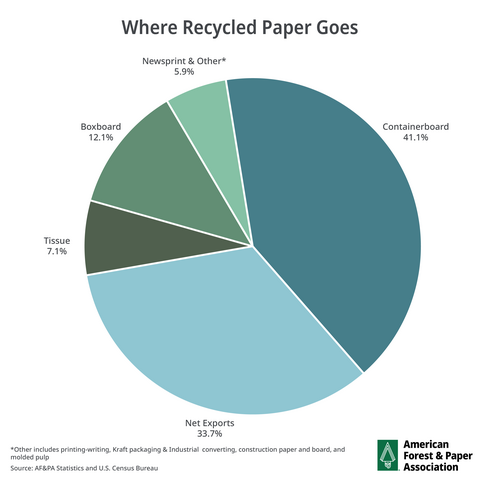

Image credit: https://www.afandpa.org/. Breakdown showing where the recycled paper goes. Data source: American Forest and Paper Association.

Wood is the best source of pulp for making paper, but used paper is also a rich source of pulp. Writing and printing on paper does not remove the fiber content, and fiber eventually becomes paper.

What Are the Main Streams of Paper Waste?

The reason why our landfills are flowing with 85 million tons of paper waste every year is that we refuse to reuse paper products.

Your documents like electricity bills, phone bills, invoices, cable bills, etc., are also a form of paper waste. And instead of reusing them, they are thrown away, creating more recyclable waste.

Some of the most common streams of recyclable paper waste are:

Household Waste Paper

Household paper waste consists of all the daily paper waste products like newspapers, paperboard packaging, mails, paper print, magazines, etc.

Cardboard Waste

Cardboard wastes include thick brown cardboards from our everyday used items like parcel boxes or packaging.

Confidential Waste Paper

Most confidential paper waste, like printed documents with sensitive information, is shredded. This shredded paper is a great resource for the tissue industry.

Why is Paper Recycling Important?

The major benefits of paper recycling are linked to environmental advantages like:

- Saving spaces in landfills

- Reducing energy and water consumption by 28% to 70%

- Preserving resources and saving the forests

- Reducing carbon footprints and greenhouse gas emissions

- Generating less pollution

Here’s How the Process of Recycling Paper Works:

Various steps involved in paper recycling process.

-

Step 1

Collection

The first step of the paper recycling process involves recyclers and paper merchants collecting paper waste from bins and combining it in a large recycling container. It’s worth mentioning that contaminated paper cannot be accepted for recycling of paper. So, the paper has to be gathered separately without it mixing with other products.

-

Step 2

Sorting and Transportation

The paper is then measured and graded for quality. Grading paper according to its properties is essential because paper with similar properties has similar amounts of fibers that can be extracted from the pulp.

The graded paper is then taken to the paper recycling business facility where its quality and quantity are measured. This step determines whether the paper is accepted or rejected; if accepted, the purchase contract is issued to the recycler.

The accepted paper is then further sorted depending on its surface treatment and structure. In this step, the paper is arranged into different categories such as papers, magazines, newspapers, office paper, etc. Sorting is an essential step because the sorted paper is then treated differently in the next stages to generate different recycled paper types.

-

Step 3

Shredding and Pulping

The paper is shredded into small bits. A large quantity of water and chemicals like sodium hydroxide, hydrogen peroxide, and sodium silicate are added to the shredded paper to break it down into paper fibers.

This forms a slurry solution, also known as pulp, a material for making recycled paper. The process of converting recycled paper into pulp is called pulping.

-

Step 4

Screening

Once pulp is formed in the previous process, it is screened. The screening process consists of pushing the pulp into screens with holes and spaces of various sizes and shapes. At the end of this procedure, you get contamination removed from the pulp.

-

Step 5

De-Inking

At this stage, the cleaned pulp is added through more series of screens to remove even larger containment pieces like staples, ink, glue, or plastic film. Old pulp is mixed with this pulp to form firmer products and then placed in a machine to clean more of the paper pulp debris. It filters impurities like tape, strings, or glue. The heavy materials will fall on the bottom, while the light ones will float on top.

The filtration is done in two ways. In the first method, ink prints are removed through chemical additives with washing and rinsing. This method is used for tiny ink prints.

While the second method – flotation, is used to remove larger blobs of ink. Here, air bubbles are used. Ink and other substances stick to these bubbles and float on top where they are removed.

-

Step 6

Bleaching

This stage is intended to produce white paper. Hydrogen peroxide is added to boost the paper’s whiteness, brightness, and purity. If producing brown cardboard is your intention, you should skip bleaching. However, if you want to produce paper with coloring, adding color stripping materials is essential to remove dyes from the paper. The entire motive of bleaching is to clean the pulp and make it ready for the final processing stages.

-

Step 7

Drying

In this step, the pulp is made to pass through rollers where the excess water is pressed out. A vibrating machine can also be used to make the pulp 50% water and 50% fiber. The pulp can be used by itself, or virgin wood fiber can be added to give extra strength and smoothness to the paper.

-

Step 8

Rolling

At the final stage of the paper recycling process, you prepare the pulp to convert it into new paper sheets. The pulp is mixed with hot water and chemicals and placed inside a machine with press rollers.

Later, a heated metal roller draws extra moisture out from the pulp. It is then mixed with new production materials on a dry flat conveyor belt and heated cylindrical surface. When the pulp turns solid, it is transferred to steam-heated cylinders to form continuous paper sheets.

The paper sheet is turned into different sizes and shapes. These sheets are used in printing papers, wrapping papers, cellulose insulators, newspaper printing, etc.

What Paper Can be Recycled?

Not all types of paper can be recycled, but most can. These include:

- Old Corrugated Containers/Cardboard – Commonly consists of layers of paper joined together with a ruffled or grooved inner liner

- Double Line Kraft – Double line cuttings from corrugated boxes

- Old Newsprint – Old newspapers that have been read or were printed with extra issues

- White Ledger – Non-glossy and printed/non-printed white letterhead, typing/writing, and copy machine paper

- Colored Ledger – Non-glossy and printed/non-printed colored paper

- Coated Book Stock – Coated free sheet paper

- Computer Print-Out – Color barred or blank computer paper (commercial forms or primers’ inks may not be accepted by recycling centers)

- Phone Books – New/used telephone books

- Magazines – Used issue magazine copies, which could be pre-sorted or baled

- Sorted Office Waste – Various kinds of papers collected from offices and organizations, like notepads, booklets, fliers, white/pastel copy and writing paper, white/multi-stripe computer paper, letterheads, and envelopes etc.

- Mixed Paper – Variety of papers that have not been sorted may include office papers as well as newsprint, magazines, etc.

What Paper is Not Recyclable?

As mentioned above, not every paper is recyclable. This list includes:

- Paper with food waste like pizza boxes

- Shredded paper waste

- Laminated paper

- Towels, napkins, tissue paper

- Treated or coated paper

- Foil-coated paper

- Wallpaper with glue residues

- Paper contaminated with grease, oil, or chemicals

- Wax paper

Recycle Shredded Paper

Separate the shredded paper from your usual recycle bin because the paper fibers are too small and broken to be processed by a huge recycling facility. It may get stuck inside the machinery parts.

Recycling shredded paper is complicated but not impossible. Consider reusing them in your home by making them a packaging material.

How Does Recycling Actually Work? – American Forest and Paper Association

What Are the Examples of Recycled Paper Products?

We use recycled paper in our daily lives without even knowing it. Statistics say that an estimated 200 million tons of paper and cardboard are manufactured annually from recycled paper sources.

The most common examples of products made from recycled paper are as follows:

- Magazine and newspapers

- Toilet paper and tissues

- White printing paper

- Greeting cards

- Paper towels and napkins

- Cardboard

It is essential to note that paper recycling is not comparable to other types of recycling, such as aluminum recycling. With metals, the metallic properties are retained after repeated recycling, but recycling paper leads to reduction in the length of fibers. Eventually, recycled paper will reach a point where it can no longer be recycled.

One of the best options to recycle paper is to use paper shredder, a mechanical device which cut paper into chad, strips, or fine particles. You could also invest in a document shredder that cuts up materials, which makes it ideal for manufacturing industries, large offices and small businesses.

What Are the Benefits of Recycling Paper?

Virgin paper will always be superior to recycled paper for many applications, but recycled paper has some incredible advantages too:

- Sustainability – Forests are getting depleted and the desire for environmental well-being has led to the Sustainable Forestry Initiative (SFI), which combines the continuous growing and harvesting of trees with long-term protection of wildlife, plants, soil, and water quality.

- Environmental Impact – The primary component of paper is wood pulp, which is obtained from trees. Recycling paper results in reduced usage of wood as the raw material, which means less forest depletion and a host of environmental benefits.

- Reduction of Emissions – Less energy is spent on recycling paper which ensures that fewer greenhouse gases are released into the atmosphere. Since decomposition causes methane emissions, recycling paper cuts these down too.

- Fiber Supply – Recycled paper ensures that the available supply of fresh fiber is extended. This leads to carbon sequestration, which means more carbon in the soil.

- Landfill Space – As more paper is recycled, less land is filled with waste paper. This saves the scarcest resource of all, i.e., land.

- Water Consumption – Virgin paper production consumes a lot more water than recycling paper, so a substantial amount of water is saved through waste paper recycling.

- Waste Disposal – Paper forms a huge component of everyday waste and tends to solidify, increasing the weight. Recycling paper means less waste to deal with.

Explain The Environmental Benefits Of Recycling Paper Products.

By using recycled paper to create new paper, fewer trees are cut down, protecting natural resources. Recycling services can sometimes be more affordable than garbage disposal services. Paper recycling minimizes air pollution from burning and frees up space in landfills.

What Are the Different Grades of Recyclable Paper?

An important aspect of paper recycling is the grade of the paper. Paper is recycled over and over up to 7 times. And as it is recycled, the paper fibers become shorter until they are of no use. And the length of the fiber is what determines the grade of the paper. There are typically 5 grades; let’s understand each.

- Old Corrugated Containers – Also known as corrugated cardboards, their use can be seen in product packaging.

- Mixed Paper – Mixed paper is a broad category that covers paper used for phonebooks, mails, magazines, books, etc.

- Old Newspapers – This category consists of newsprint, tissue papers, and other similar products. It is a lower-grade paper created in mills using newspapers.

- High-Grade Deinked Paper – This category covers copy paper, envelops, letterheads, etc. that go through the process where ink is removed from them.

- Pulp Substitutes – It is the scrap that mills discard and is usually of no use. However, you may find it in some products you use.

Paper is one of the everyday products that will continue to find heavy usage, even in these digital times. By recycling paper, incredible environmental advantages await in exchange for a small sacrifice in paper quality!

FAQs

-

Where to recycle paper?

You can simply place paper waste for recycling in your city recycling bins. Contact your local waste management company to take care of it.

-

Is recycled paper eco-friendly?

Paper made of virgin material is less sustainable than recycled paper. Recycled paper requires less energy, reduces water pollution, saves trees, and conserves wood. Hence, recycled paper is more eco-friendly!

-

Can you recycle ink-printed paper?

Yes, you can recycle paper with ink since the recycling process goes through the stage of de-inking, where the ink is removed from the pulp before a recycled paper is made.

Content resource:

- https://earth911.com/business-policy/paper-recycling-details-basics/

- https://www.afandpa.org/priorities/recycling/does-paper-actually-get-recycled

- https://www.usi.edu/recycle/paper-recycling-facts/

- https://www.recycling.com/paper-recycling/

Compactor Management Company (former Northern California Compactors, Inc.) offers installation and support services for waste recycling equipment such as waste compactors, balers, shredders & conveyor systems. Established in 1981, it offers waste management solutions across the United States.